Blog

30

2024

-

07

What are the measures taken by professional polyacrylamide manufacturers in terms of cost control

In the field of polyacrylamide production, cost control is one of the key factors for manufacturers to maintain competitiveness and achieve sustainable development. So, what measures do professional polyacrylamide manufacturers usually take to effectively control costs?

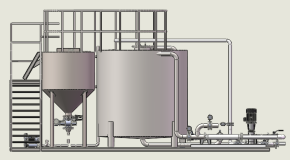

First of all, optimizing the production process is an important part. Through continuous research and improvement of polymerization reaction conditions, such as precise control of temperature, pressure, reaction time and other parameters, the reaction efficiency can be improved, and the waste of raw materials and energy consumption can be reduced. At the same time, the use of more advanced production technology and equipment can improve the degree of automation of production, reduce labor costs, and reduce the error and defective rate in the production process.

The procurement strategy of raw materials also has a significant impact on cost control. Manufacturers will establish long-term and stable cooperative relations with high-quality raw material suppliers, and obtain more favorable prices through large-scale procurement. In addition, we will pay close attention to the price fluctuation of the raw material market and arrange the purchase timing reasonably to reduce the cost of raw materials.

In terms of energy management, manufacturers will pay attention to the implementation of energy saving measures. For example, energy-saving renovation of production equipment, the use of efficient motors and energy-saving lighting systems, and the optimization of the plant's energy layout and distribution, thereby reducing energy consumption.

Inventory management is also an important part of cost control. Reasonable control of the inventory level of raw materials and finished products, to avoid the inventory backlog caused by capital occupation and storage costs increase, but also to ensure that can meet customer orders in a timely manner, which requires accurate market forecasting and efficient supply chain management.

The rational allocation of human resources can not be ignored. By optimizing the post setting, improving the work efficiency and skill level of employees, the utilization of human resources is realized. In addition, staff training will be strengthened to reduce production accidents and losses caused by improper operation.

Quality control in the production process is also an effective means to reduce costs. Strictly controlling product quality and reducing the production of defective products and waste products can not only reduce production costs, but also maintain the good reputation of the enterprise and avoid after-sales costs and customer loss caused by quality problems.

R & D investment is also a long-term way to control costs. Through the research and development of new production process and product formula, improve the performance and production efficiency of polyacrylamide, so as to reduce the unit cost at the same time, to provide customers with more cost-effective products.

In addition, manufacturers will also pay attention to waste treatment and recycling in the production process. Effective treatment of waste water and waste gas, while meeting environmental protection standards, try to recover useful substances from them, realize the recycling of resources, and reduce environmental protection costs.

In summary, polyacrylamide professional manufacturers through the optimization of production processes, rational procurement of raw materials, effective management of energy and inventory, optimize the allocation of human resources, strict quality control, increase investment in research and development and focus on waste treatment and recycling and a series of measures to achieve effective cost control. This will not only help manufacturers maintain their price advantage in the market competition, but also provide customers with better quality and more cost-effective products, and promote the healthy development of the entire industry.

Latest information