Blog

2024-12-19

Enterprise Flagship | Peng Yiyun: Innovation Fills Technological Gaps, Entrepreneurship Protects Water Environment Safety

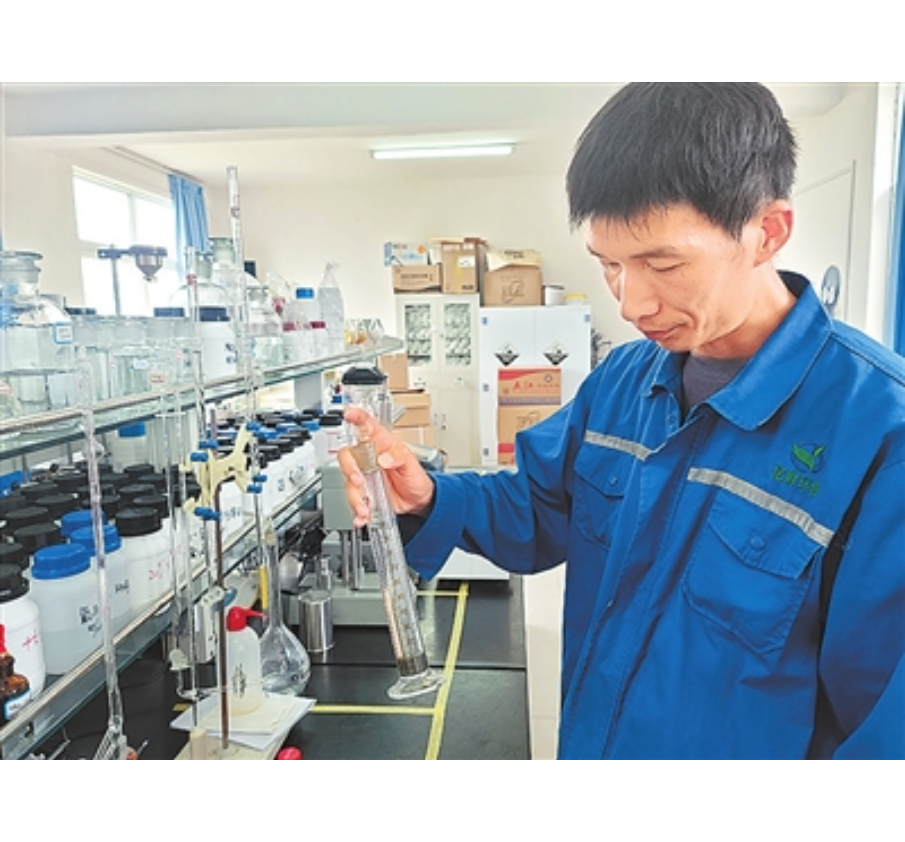

Flocculant 'catches iron' in water

2024-12-19

Add a few drops of solution to the muddy iron mine water, shake it up and down a few times, and the iron impurities will sink to the bottom of the tube, leaving the upper layer of iron mine water clear.

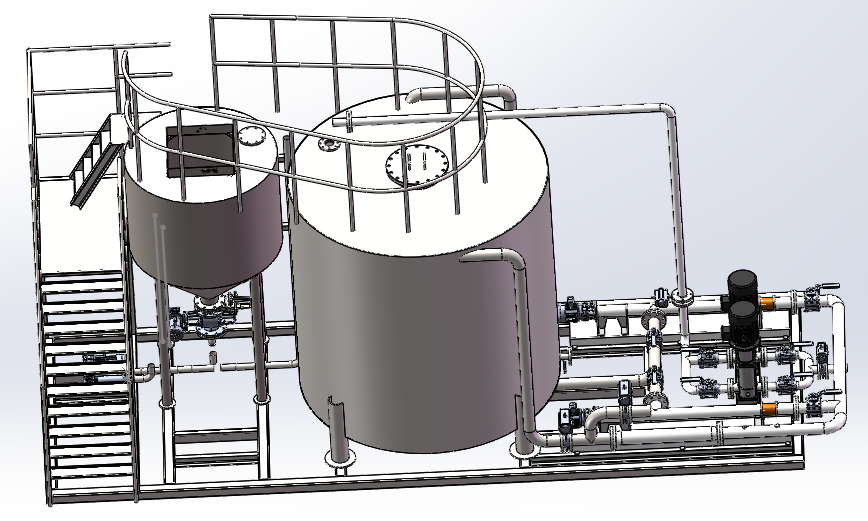

City leaders visit Henan Yiqun to investigate the progress of the Phase II project

2024-12-19

On December 17, 2024, Yuan Ruifeng, Secretary of the Yima Municipal Party Committee, and Zhou Qiang, Member of the Standing Committee of the Municipal Party Committee and Executive Deputy Mayor, visited the construction site of the Phase II project of Henan Yiqun Environmental Protection Technology Co., Ltd. for an inspection.

The impact mechanism of different formulations on the properties of polyacrylamide emulsion

2024-10-29

The type and proportion of monomers are key factors affecting the performance of polyacrylamide emulsion. Acrylamide, as the main monomer, when copolymerized with other functional monomers, imparts different properties to the emulsion. For example, the introduction of anionic monomers such as acrylic acid can give the polyacrylamide emulsion a negative charge. This negatively charged emulsion, in wastewater treatment, can effectively remove suspended particles from wastewater through charge neutralization and adsorption bridging. If the proportion of acrylic acid is increased, the negative charge density of the emulsion increases, and the flocculation effect on positively charged pollutants will be enhanced, but an excessive amount may lead to a decrease in emulsion stability, because excessive charges can cause excessive intermolecular repulsion. The choice and dosage of initiator also have an important impact on the performance of polyacrylamide emulsion. The initiator's role is to initiate the monomer polymerization reaction. Different initiators have different decomposition temperatures and initiation efficiencies. Ammonium persulfate is one of the commonly used initiators, and its dosage determines the rate of the polymerization reaction. If the dosage is too low, the polymerization will be incomplete, resulting in a lower molecular weight of polyacrylamide, affecting the viscosity and flocculation performance of the emulsion. If the dosage is too high, it may cause side reactions, resulting in impurities in the emulsion, reducing the purity and stability of the emulsion. The type and amount of emulsifier cannot be ignored in the polyacrylamide emulsion formulation.

2024-10-29

On October 28, 2024, Yiqun Environmental Protection successfully carried out a comprehensive audit by the expert group of the QES three-system certification audit body. The purpose of this audit is to ensure that the company's quality, environment and occupational health and safety management systems continue to improve and meet international standards.

Polyacrylamide emulsion using what polymerization process, how to ensure product quality?

2024-09-29

Polyacrylamide emulsion plays an important role in many fields, and its performance and quality are directly related to the application effect. So, what kind of polymerization process is used in polyacrylamide emulsion, and how to ensure the quality of its products? In terms of polymerization process, there are many commonly used methods. Among them, emulsion polymerization is a more common way. This process forms a stable emulsion system by reacting monomers, initiators, etc. in an aqueous phase. In the polymerization process, it is necessary to accurately control the reaction conditions, such as temperature, stirring speed, etc., to ensure the smooth progress of the polymerization reaction. In addition, microemulsion polymerization is also a process worthy of attention. It can be carried out under milder conditions, and the resulting emulsion has a smaller particle size and a more uniform distribution, thereby improving the performance of the product. At the same time, some advanced polymerization technologies are also being developed and applied, bringing new possibilities for the production of polyacrylamide emulsions. To ensure the quality of polyacrylamide emulsion, we must first start with the choice of raw materials. High-quality monomers and additives are the basis for the production of high-quality products. Only by selecting pure and stable raw materials can the performance and stability of the product be guaranteed. In the production process, strict quality control is essential. From reaction monitoring to product

Factors Affecting the Viscosity of Polyacrylamide Emulsion

2024-08-30

Polyacrylamide emulsion is widely used in many industrial fields because of its unique properties. As an important physical property, viscosity is affected by many factors. In-depth understanding of these factors and their specific effects on viscosity data and variation rules is of great significance for the correct use and optimization of polyacrylamide emulsions. Effect of 1. temperature Temperature is an important factor affecting the viscosity of polyacrylamide emulsion. Generally speaking, with the increase of temperature, the viscosity of polyacrylamide emulsion will gradually decrease. This is because the increase in temperature will increase the thermal motion of molecules, so that the interaction between molecules is weakened. For example, at room temperature 25 ℃, the viscosity of a particular type of polyacrylamide emulsion may be 5000 mPa · s (mPa · s), when the temperature rises to 50 ℃, its viscosity may drop to about 3000 mPa · s. In practical applications, if it is in the field of sewage treatment, when the temperature is high in summer, it is necessary to appropriately adjust the amount of polyacrylamide emulsion added according to temperature changes. Because the decrease of viscosity may lead to the decrease of flocculation effect, it is necessary to increase the dosage to ensure the treatment effect. In some scenarios that require pipeline transportation, higher temperatures are higher.

2024-08-23

On the morning of August 22, 2024, Yao Zhenbo, deputy secretary of the municipal party committee and mayor, and his party visited Henan Yiqun Environmental Protection Technology Co., Ltd. to conduct field research on the progress of the company's second phase project.

2024-08-23

On the morning of August 22, 2024, Dong Shuliang, deputy secretary and vice chairman of the Party group of Sanmenxia CPPCC, Liu Kuanhai, deputy secretary of the Party group of Sanmenxia CPPCC, and Nan Libo, member of the Party group and deputy director of Sanmenxia Bureau of industry and information technology, visited our company to conduct in-depth investigation on key projects and enterprise operation.

2024-08-19

As a multifunctional polymer, polyacrylamide is widely used in many industries. However, the application scenarios and needs of different industries vary greatly, which requires manufacturers to accurately adjust the production process and product performance indicators to meet the special requirements of various industries. In the field of sewage treatment, polyacrylamide mainly plays a key role in flocculation and sedimentation. In order to meet the needs of sewage treatment, the production process needs to focus on the control of the ion degree and molecular weight of the product. For urban sewage treatment, the general selection of medium molecular weight and medium plasma polyacrylamide products. In the production process, the molecular weight can be precisely controlled within a suitable range by adjusting the polymerization conditions, such as the type and amount of the initiator, the reaction temperature and time, etc. For example, appropriately lowering the reaction temperature and prolonging the reaction time help to increase the molecular weight and enhance the flocculation effect. Meanwhile, the adjustment of the ionicity can be achieved by controlling the amount of the functional monomer added. In sewage treatment, polyacrylamide is required to be able to quickly combine with suspended solids in sewage to form larger flocs, which is convenient for subsequent precipitation and separation. Therefore, the dissolution properties of the product are also crucial. Manufacturers can optimize the drying process