Product Series

Automatic Polyacrylamide Melting Machine

Online Message>

Keywords: billion groups of environmental protection

Category: Products

Product Details

1. Product Overview

Continuous flocculant rapid dissolution device (also known as "automatic dosing system") is a special equipment for adding, preparing and storing drugs, which can realize the automatic preparation of flocculant liquid and continuously add the prepared solution to the industrial process. It is mainly used in sewage treatment processes such as sedimentation, coagulation, air flotation and sludge dewatering for automatic configuration and dosing of coagulant or flocculant. The preparation of raw materials is powder or small granular pharmaceutical, such as powdered polyacrylamide (PAM). The continuous flocculant rapid dissolution device is arranged in an integrated manner, with compact structure, small footprint, low energy consumption, simple operation, convenient maintenance and good adaptability. The high degree of automation overcomes the unfavorable factors such as low accuracy and poor effect of manual preparation, greatly improves the preparation ability of flocculant, and is more efficient, energy-saving and environmentally friendly than traditional manual preparation. And the water inlet to medium level system continues to operate automatically. This device is composed of a high degree of automation, stable performance, reliable operation and simple menu operation.

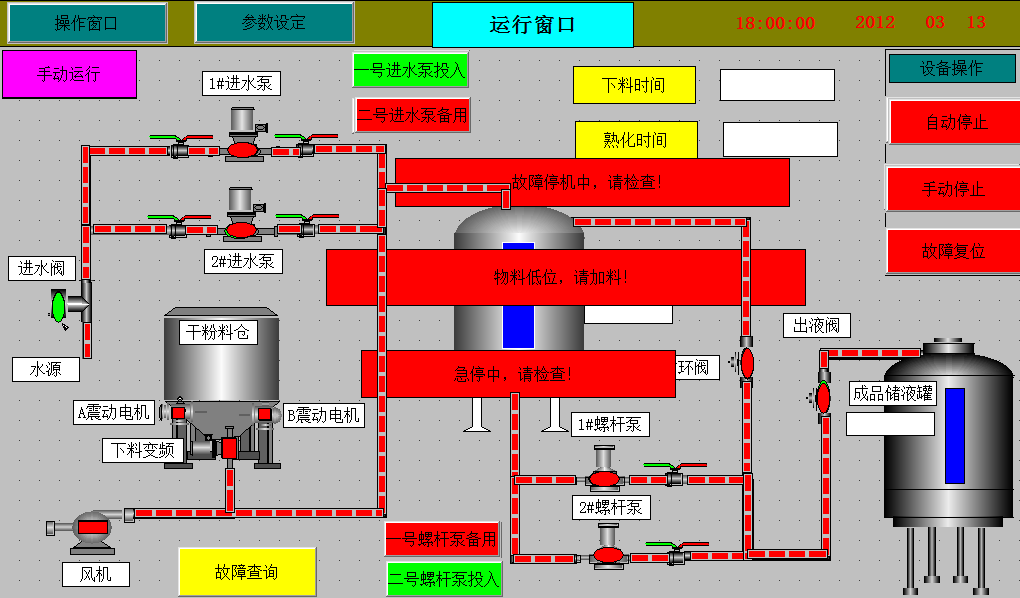

Introduction of automatic control system for 2. flocculant preparation

The automatic control system of flocculant preparation adopts Siemens S7-1200 controller, which has the advantages of strong durability and strong anti-interference ability. The signals of field instruments and electrical are sent to EP01 control cabinet through hard wiring, and the signals that need to be controlled enter the controller. The controller calculates and processes the data. The controller is connected with the touch screen through a network cable, and the parameters and operating status of the field electrical and instrument are displayed on the touch screen and operated.

3. Process Flow Description

1. Preparation of dry powder flocculant

Picture: Preparation of Dry Powder Flocculant

The preparation of dry powder flocculant is shown in the above figure. The dry powder hopper stores the dry powder, and the dry powder is sent to the humidifier and the prepared water is evenly mixed into the mixing tank through electric shock, unloader and blower. Among them, the unloader uses frequency conversion speed regulation, which can adjust the amount of dry powder to change the concentration of flocculant. The control of the addition amount of solid flocculant is different from that of liquid, because there is no good method to measure, it is necessary to determine the flow rate of solid flocculant per minute under a fixed condition by means of calibration in advance. The specific method is as follows: remove the connection between the fan and the star, place the container directly at the outlet of the feeder, turn on the electric vibration and the star feeder, after a period of time, weigh the weight of the solid flocculant in the container, and divide by the time to obtain the amount of material per minute. Multiple tests result in an average, which is the final traffic data. This calibration process should be carried out at regular intervals to maintain the accuracy of the weighing. The operator calculates the required amount of solid flocculant according to the required concentration of powdered flocculant, the effective volume of the mixing tank and the volume to be prepared, and divides it by the flow data to obtain the running time (in seconds) of the spiral or star feeder, and automatically controls the adding time of the solid flocculant, thus accurately controlling the feeding amount. The main outlet pipe of the circulating transfer pump has two branches, one enters the mixing tank and the other enters the finished product tank; each branch is equipped with a pneumatic butterfly valve, which is a circulating valve and a conveying valve. When circulating, the circulating valve is opened and the conveying valve is closed, and the circulating conveying pump circulates the flocculant in the mixing tank for many times to reach the required finished flocculant. After the mixing is completed, open the conveying valve first and then start the circulating conveying pump to convey the finished product to the dry powder finished product tank. Whenever the liquid level of the finished product solution tank is lower than a certain value, the circulating transfer pump is automatically started to transfer all the finished product solution configured in the mixing tank to the finished product solution tank. When the liquid in the mixing tank is delivered to the finished product tank, the system automatically opens the water inlet valve on the top of the mixing tank, the water is delivered to the humidification head on the top of the mixing tank, the dry powder flocculant delivery is started, and the fan, star feeder and electric vibration feeder are started in sequence. Flocculant is transported to the humidifying head by wind, and mixed with water into the mixing tank. In order to ensure the mixing effect and ensure the normal dissolution of the flocculant, when the preparation tank is started and the preparation of the flocculant is started, the mixing/delivery pump to which the mixing tank belongs is started at the same time. The characteristics of dry powder flocculant can not be dissolved immediately after mixing with water, and the effect can only be achieved after a period of mixing. After a given time (adjustable) of mixing, the system considers that the effect is achieved, switches the valve flow direction, and delivers the finished flocculant solution to the finished product solution tank.

Scope of application of 4. products

It is mainly used in sewage treatment processes such as sedimentation, coagulation, air flotation and sludge dewatering for automatic configuration and dosing of coagulant or flocculant. The preparation of raw materials is powder or small granular pharmaceutical, such as powdered polyacrylamide (PAM).

1) Wastewater treatment: flocculation treatment of urban or industrial wastewater, treatment of sewage dehydration process, tertiary or tertiary treatment of municipal wastewater;

2) Drinking water treatment: water plant using surface water as water source, as water purification agent and flocculant dosing system;

3) process dosing: food, beverage, pharmaceutical industry process dosing, chemical, petroleum, pulp and paper industry process dosing;

4) other industries: electroplating, food and beverage industry wastewater treatment, ore smelting industry wastewater treatment.

5. product structure and performance characteristics

1. Features of product structure

1) Highly integrated integrated equipment, compact structure, small footprint, light weight, easy to install, use and maintain

2) continuous preparation, the equipment structure is firm, easy to operate, maintenance, cleaning to ensure dispersion, curing thoroughly;

3) The star feeder with special structure is adopted, and the discharge of powder outlet is uniform and reliable;

4) Nuclear Sheng dry powder humidification sprayer and components (humidifier), dry powder agent dissolution effect is good;

5) The circulating delivery pump is designed reasonably. When circulating and mixing, it not only maximizes the dissolution rate of the drug but also fully ensures that the molecular chain is not destroyed, the activity of the drug will not be degraded, and the drug effect is high. The fastest delivery to the finished product tank during delivery to ensure the supply of the dosage of the drug.

6) The control cabinet is all stainless steel shell; high-quality accessories, reliable quality, good corrosion resistance, easy maintenance, and exquisite appearance;

7) Modular combination and series configuration to meet the different needs of users.

2. Performance characteristics

1) Good corrosion resistance, all stainless steel design in contact with the medium.

2) The star feeder can deliver with high precision, the concentration of the finished solution is accurately adjustable, and the concentration is stable; it can ensure the continuous and uninterrupted supply of the liquid medicine, and the liquid medicine is homogeneous and active.

3) The concentration of the liquid medicine can be adjusted according to the actual needs. The dosage of the medicine can be accurately controlled to ensure the treatment effect and avoid waste. It can reduce the occurrence of particle (block) phenomenon caused by improper manpower allocation, which will block the pipeline or pump, and increase unnecessary personnel maintenance costs and powder expenditure costs;

4) Low energy consumption, which is 1/3~1/2 of the general similar products.

5) wide range of dissolved concentration, strong adaptability to flocculation effect of various treatment media, 0.6 ‰ ~ 5 ‰ can be adjusted arbitrarily, and the maximum dissolved amount of solid agent can reach 45 kg/h

6) Effective liquid level control, so that the stability of the system is fundamentally guaranteed

7) It is equipped with dry powder material level detection and interlocking control and alarm device with water inlet system, with high reliability

8) Strong technical support, according to customer requirements can be flexibly modified 2 boxes, single box type, according to user requirements design process;

9) flexible control, with automatic and manual control mode.

10) PLC automatic control, as long as the solid medicine into the medicine storage box, workers do not need to do other operations;

11) Good adaptability, automatic and manual operation. It can be applied to many fields.

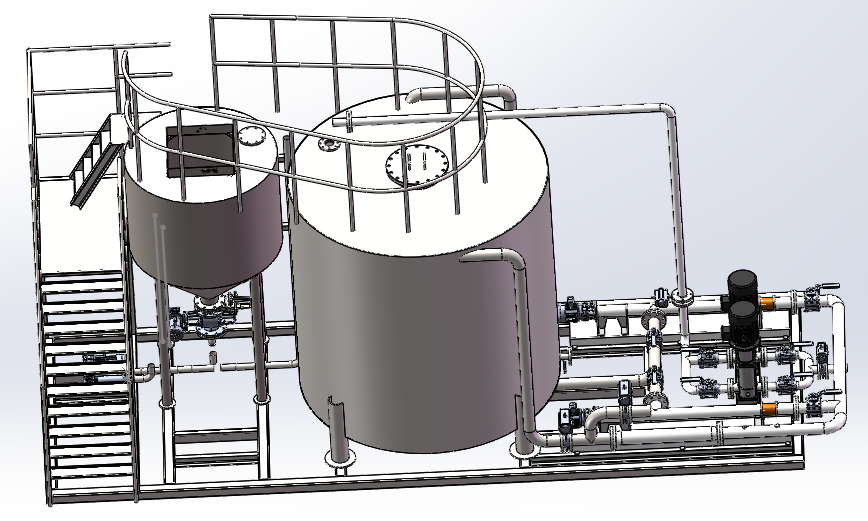

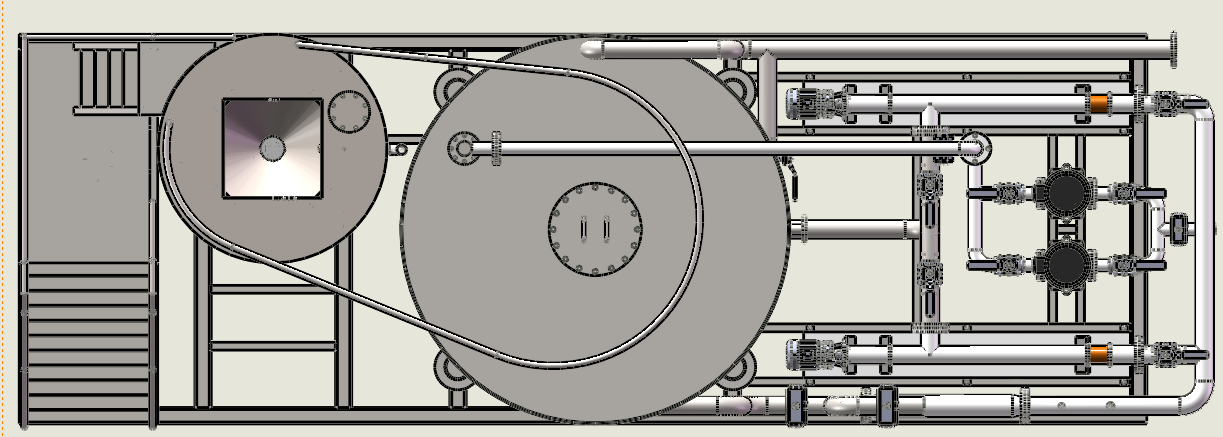

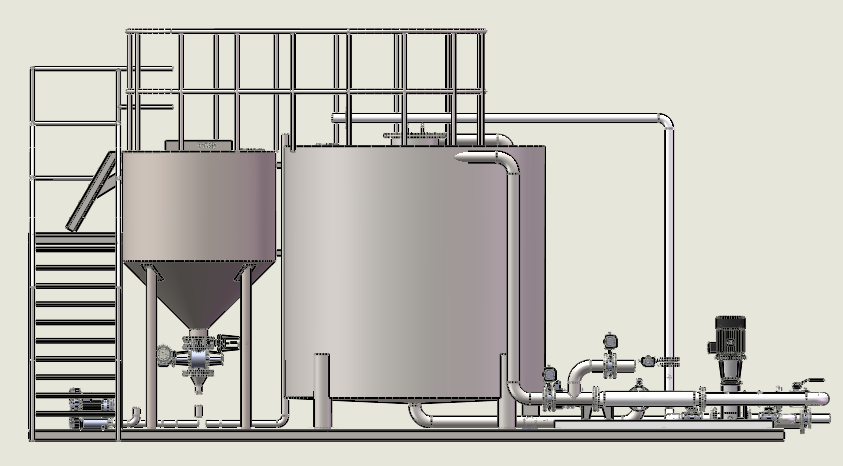

Six product composition

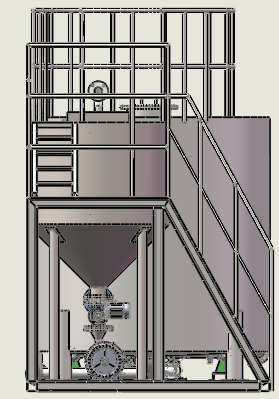

The continuous flocculant rapid dissolution device consists of a dry powder flocculant preparation frame, a circulating transfer pump group, and a dosing pump group. See the product outline and installation foundation drawing.

Preparation Frame of Dry Powder Flocculant

1, dry powder flocculant preparation frame body

The dry powder dosing system consists of control cabinet, feeder, electric shock, fan, material switch, hopper, flow detector and ladder, etc. The feeder motor adopts three-phase frequency conversion motor, which is controlled by frequency conversion according to the concentration requirements of process configuration and adjusts the dosage of dry powder. The level switch detects the amount of dry powder in the hopper and controls the start and stop of the feeder motor. Electric heating heats the dry powder at the bottom of the dry powder hopper to prevent the dry powder from being affected by moisture and agglomeration. The hopper is used to store dry powder materials with a volume of 1500L.

7. transportation and storage

This unit can only be handled after the liquid in its tank has been emptied, using suitable lifting equipment. During transportation, the tank wall must not be subjected to any external pressure. Be sure to avoid bumps and collisions. When using a forklift, the length of the fork should be able to support the width of the tank. If the crane is used, even if the device is equipped with lifting lugs, it must be fixed with slings to avoid eccentric force. Eccentric forces occurring during transport can cause damage to the tank walls and welds. The ambient temperature of the transportation and storage device should be -5°C to 50°C. As far as possible, the device should be placed in a dust-free area and protected from rain, moisture (no condensation) and direct sunlight.

Three views of supply:

- Top view

- MAIN VIEW

- Side view

Related products

Related Products

Online message

We will contact you within one working day. Please pay attention to your email.