Blog

2024-12-19

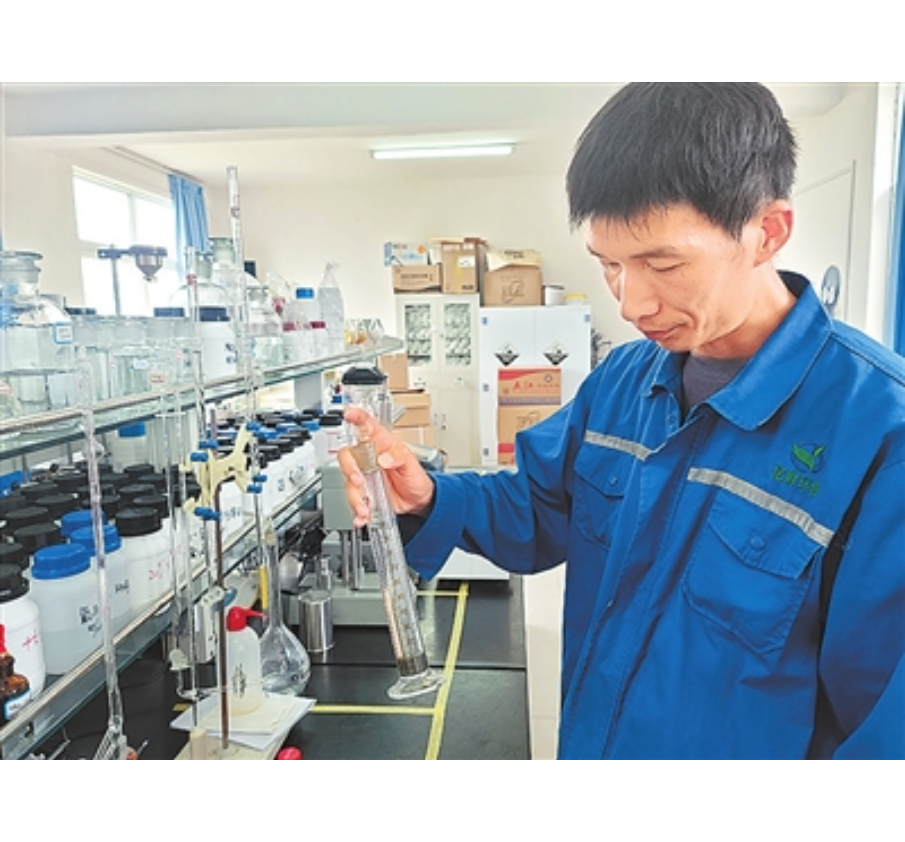

Flocculant 'catches iron' in water

2024-12-19

City leaders visit Henan Yiqun to investigate the progress of the Phase II project

2024-12-19

2024-12-17

What are the functions of polyacrylamide in drilling fluids?

2024-12-06

The role of polyacrylamide in water purification

2024-11-25

The role and application of polyacrylamide in agriculture

2024-11-12

The impact mechanism of different formulations on the properties of polyacrylamide emulsion

2024-10-29

2024-10-29

Rheological Properties and Application Effects of Polyacrylamide Emulsion

2024-10-09

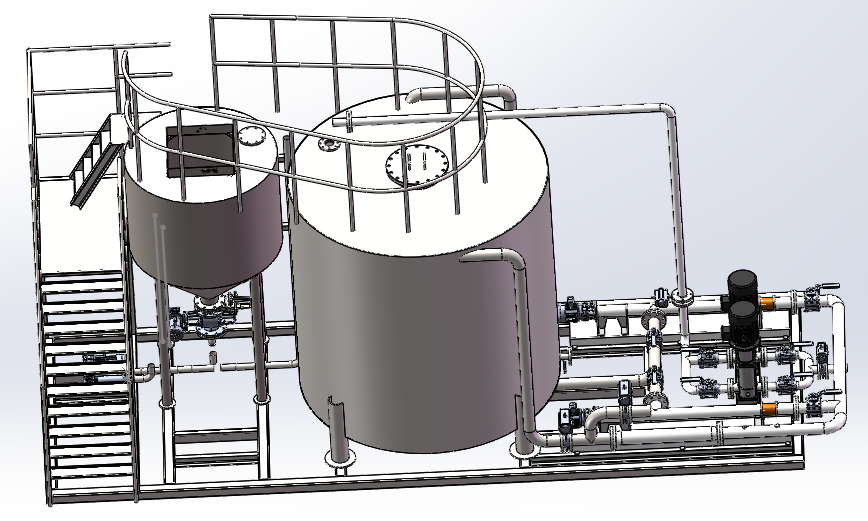

Polyacrylamide emulsion using what polymerization process, how to ensure product quality?

2024-09-29